OVERVIEW

JWC’s F-Series Flocculators for FRC DAFs efficiently coagulate and flocculate suspended solids using no moving parts or external energy inputs, such as mechanical mixers. JWC Environmental takes floc tube design very seriously, as it has a dramatic effect on the separation efficiency of solids in a Dissolved Air Flotation System.

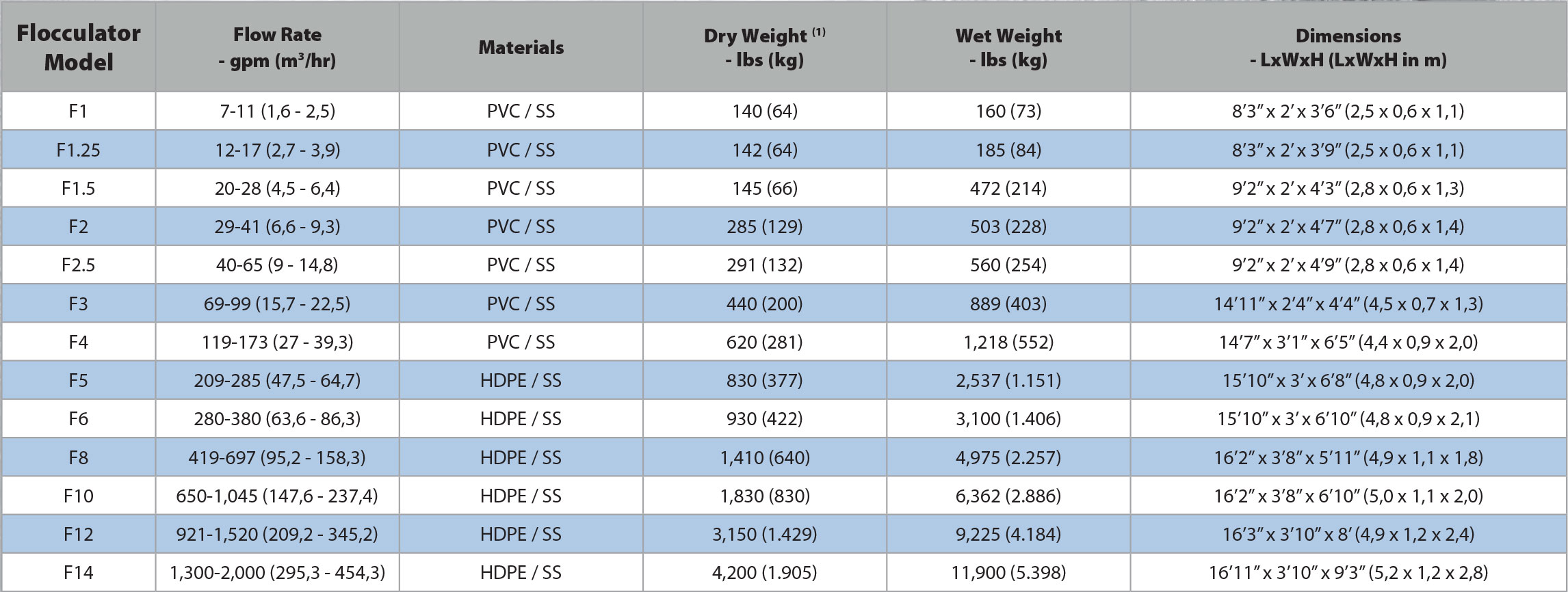

FRC Flocculators come standard with fittings for chemical dosing, sampling, and whitewater injection. Model capacities are available up to 4,000 GPM. Materials of construction available in HDPE, PVC, SS304, and SS316.

Features

In-Line Mixing Zones

To achieve proper mixing, JWC employs inline mixing zones by reducing and expanding the pipe diameter over a short pipe run. This accelerates flow-through velocity and disperses chemicals in and immediately after the mixing zone. This technique allows for increased precision over chemicals dispersion.

Wide Radius Pipe Sweeps

JWC’s F-Series Flocculators utilize sweeping, wide-radius fittings for pipe turns. This eliminates shearing at pipe bends so that flocs can grow larger over the rest of their retention time in the flocculator. By not shearing flocculated solids after formations, operators will require less chemicals to achieve the desired level of separation and clarification.

Air Injector Ports

F-Series Flocculators include air injections ports to introduce micro bubbles into the mix. This allows air to be entrained in the structure of the flocculated solids. Benefits include:

- Faster separation in DAF vessel

- Smaller DAF tank requirements

Click to enlarge