OVERVIEW

JWC Environmental’s PCL Series FRC DAFs are high-built (tall) solid/liquid separators designed for high flow rates and low solids loading rates. The PCL Series design utilizes a combination of the Sludge Dewatering Grid and a Cross-Flow Plate Pack to generate sludge with high dry solids content.

Features

Cross-Flow Plate Pack

The PCL Series FRC DAFs utilize inclined corrugated plate packs within the high-built tanks. Water is introduced to the plate packs in a Cross-Flow configuration, reducing the distance solids have to float to be effectively separated. This provides for effective solids liquid separation in a smaller floor footprint.

Air Dissolving Tube with ANSI Pumps

The PCL Series utilize the FRC angled air dissolving tube and an ANSI standard, non-proprietary pump to generate whitewater. ANSI recycle pumps bring clarified effluent to the Air Dissolving Tube where it is mixed with a small volume of compressed air until saturation is achieved. The angled configuration of the tube allows for increased water and air interface so saturation occurs almost instantly. This robust and efficient system eliminates the need for costly specialty whitewater pumps.

Sludge Dewatering Grid

PCL Series FRC DAF systems employ the sludge Dewatering Grid, to hold sludge in place as it thickens and self-dewaters. The Dewatering Grid helps:

- Operators control sludge thickness

- Eliminate pre-mature removal of solids

- Reduce build-up and/or re-entrainment of sludge

- Generate drier sludge

As with all FRC DAF systems, the PCL series is engineered for efficiency, reliability, and ease of operation. Automated controls and instrumentation remove process uncertainty and reduce the opportunities for user error. PCL units pair perfectly with F-Series pipe flocculators and can be delivered in a turn-key fashion including controls, pumps, chemical feeders – all pre-wired, pre-plumbed, and skid mounted.

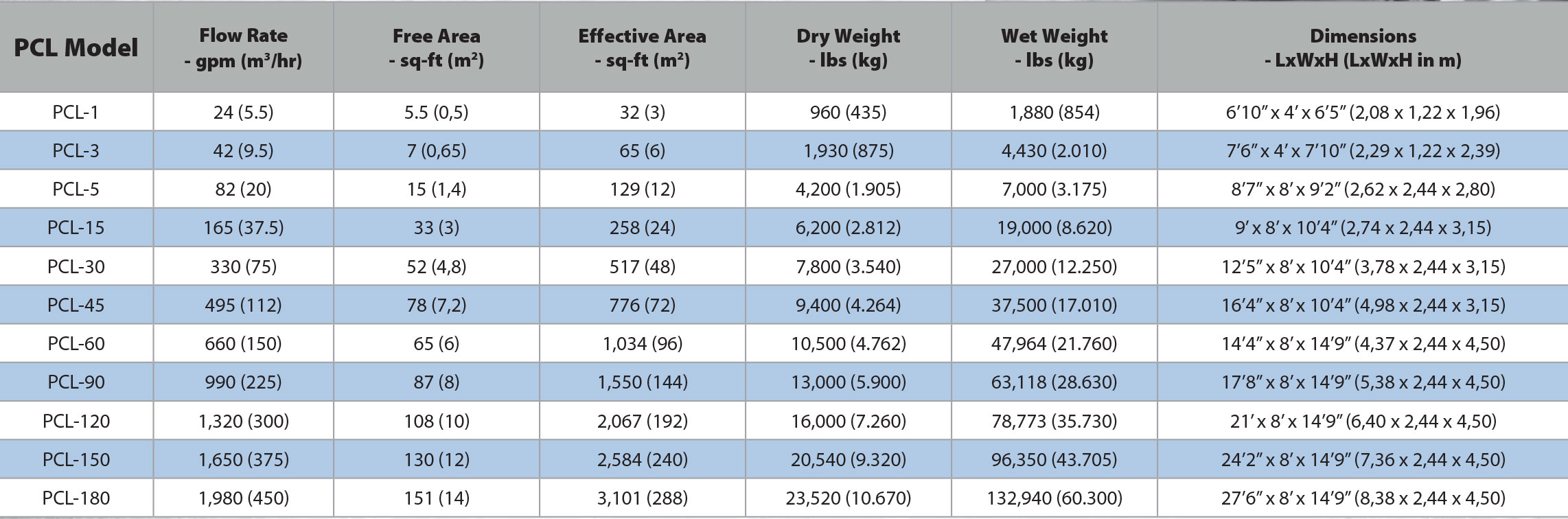

Click to enlarge